Technical sound insulation

Technical noise control: Efficient solutions for quieter surroundings

In technological and industrial settings, soundproofing has long been an important tool for lowering noise levels and improving the quality of life. In the ideal case, effective noise protection measures are already an integral part of the development process in vehicle construction, mechanical engineering and the design of production lines, among others. There is a rising demand for machines and devices that score with quiet operation. However, technical noise control measures can generally also be implemented at a later stage, in particular using sound insulation layers or noise control panels with both sound-insulation and sound-attenuation effect.

Based on our many years of experience, we can recommend the right product and the optimum solution for virtually any application. Various measures can be taken to significantly reduce noise in production halls, workshops, utility rooms and other industrial spaces. To achieve optimum soundproofing, there are various options and specific recommendations for different room types.

Applications of technical noise control

Technical noise control measures are applied in a variety of areas to solve noise problems and create a quieter and more pleasant environment:Machines and systems:

Acoustic enclosures, sound-damping materials, acoustic cabins/casings as well as insulation layers help reduce noise generated by production machines.

Factories, workshops and production halls:

Sound-absorbing materials on ceilings and walls help keep noise levels low and improve working conditions.

Advantages of technical noise control

Health and well-being:Quieter surroundings mean less stress - and minimized stress levels foster sound sleep at night and lead to overall improved health.

Productivity and efficiency:

Lower noise levels at work, whether in the office or in the production hall, support concentration and boost productivity.

Eco-friendliness:

Technical noise control measures help reduce harmful noise emissions and create a quieter environment.

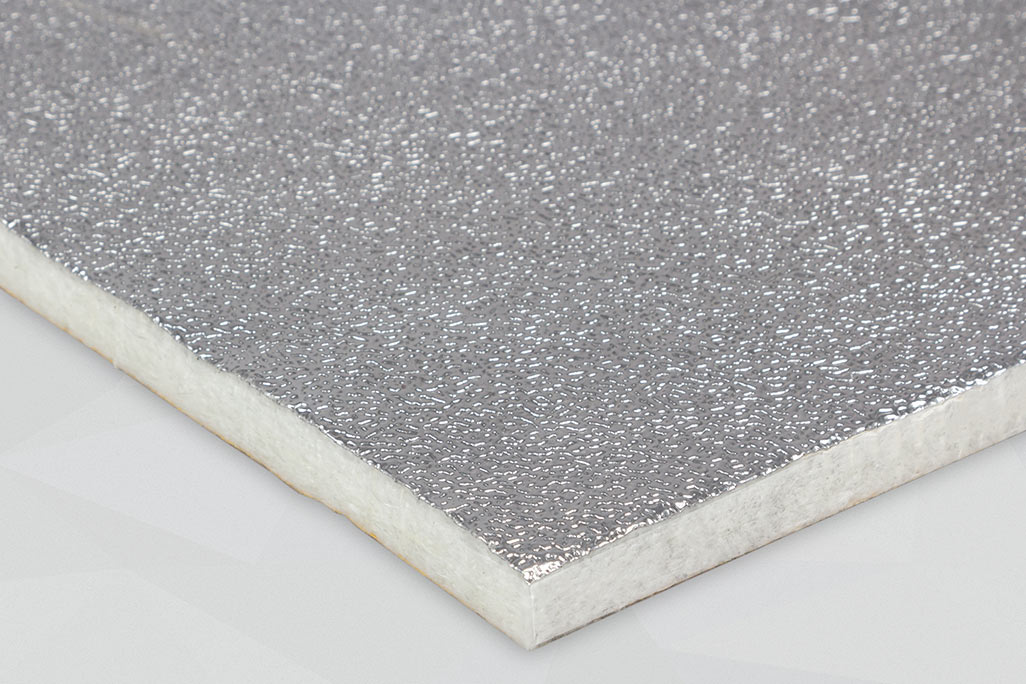

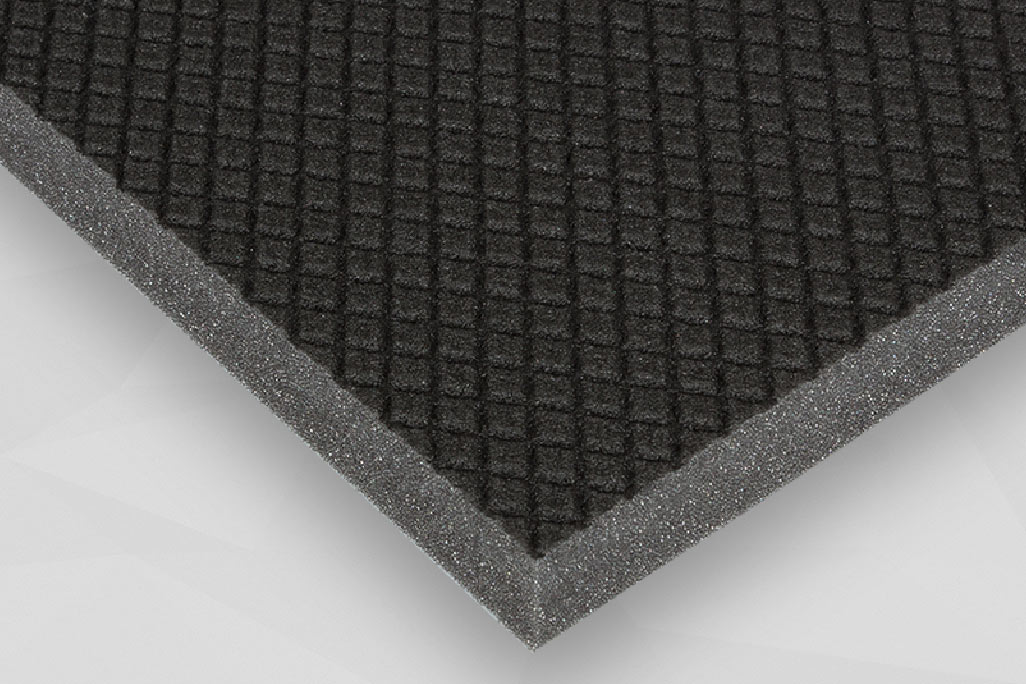

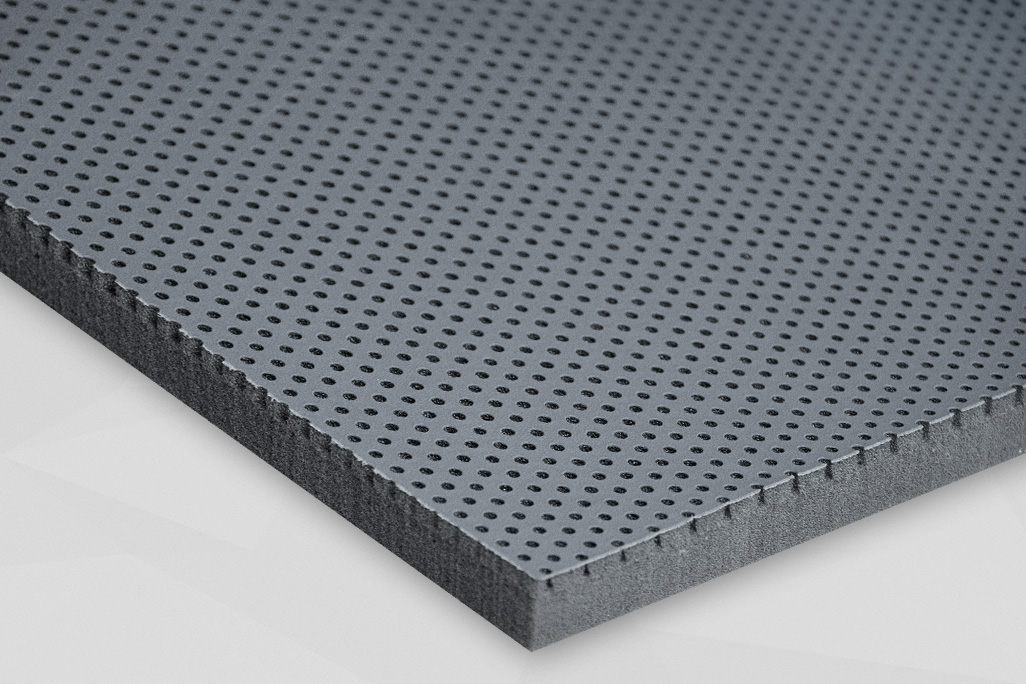

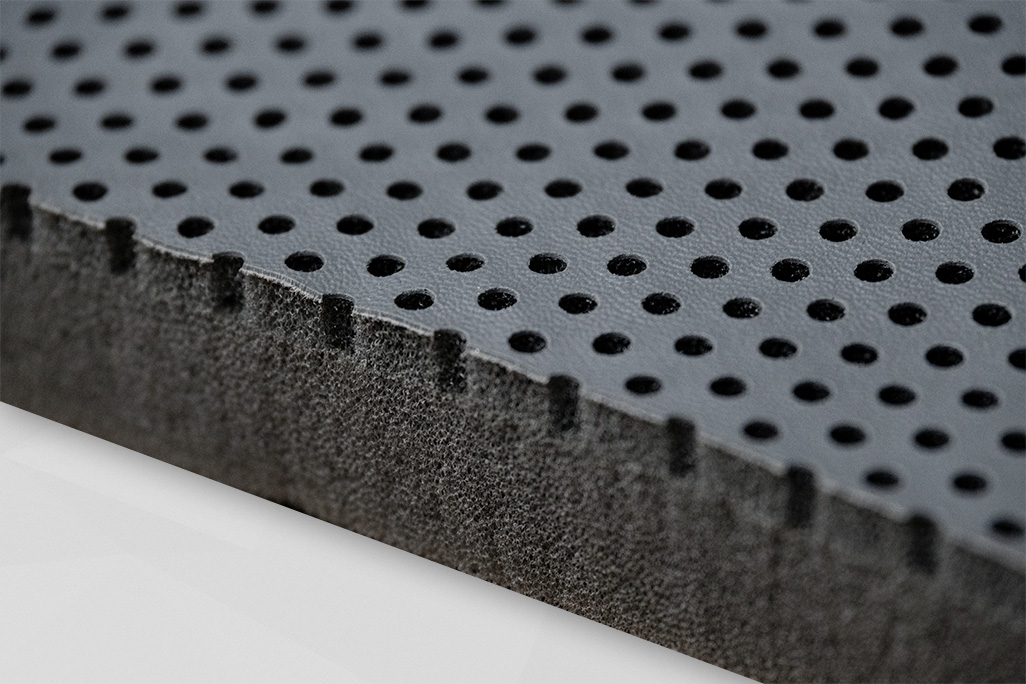

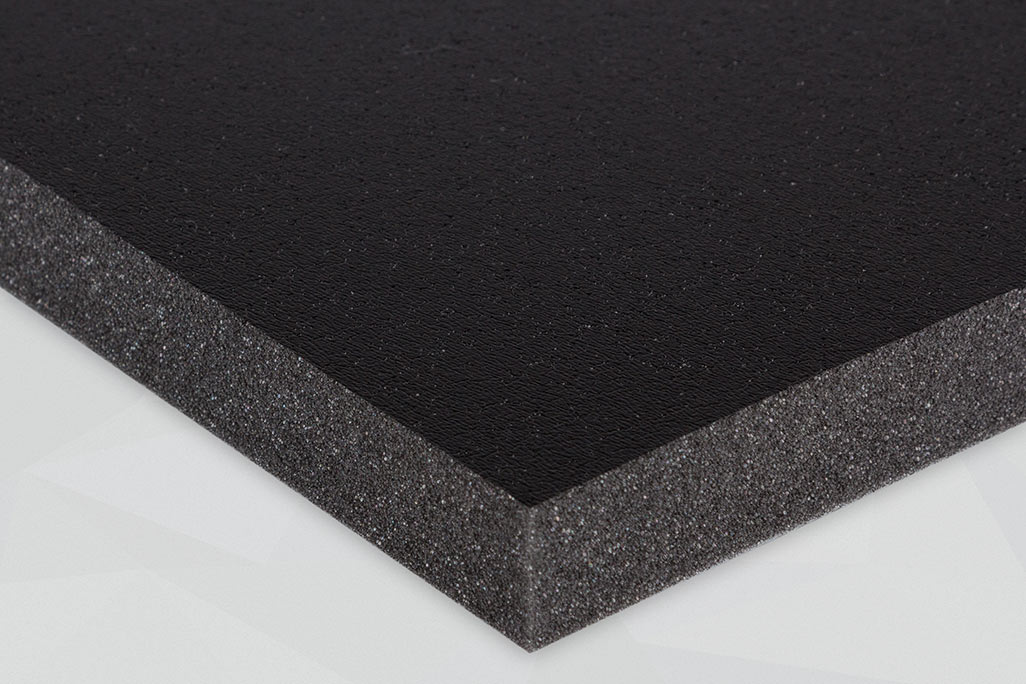

Less structure-borne noise thanks to the effective acoustic insulation of enclosures

Mechanical devices and machines often are the source of structure-borne noise. Examples include motors, pumps, compressors and ventilation systems. These devices generate vibrations that are transmitted through their housings and then spread into the surroundings in the form of audible sound. Soundproofing machine enclosures is therefore an effective method of reducing structure-borne noise and creating a quieter working and living environment.Vibrations and the resulting noise can be significantly lessened through the use of sound-attenuating materials, composite foam products or multi-layer materials consisting of foam and a heavy layer. This results in quieter and safer surroundings that support efficiency, both in industrial and domestic environments. With the high-quality sound insulation solutions from soniflex, noise pollution can be noticeably and sustainably reduced.

Content: 0.5 m² (€45.80* / 1 m²)

Content: 0.5 m² (€21.80* / 1 m²)

Content: 1.45 m² (€62.00* / 1 m²)

Content: 0.5 m² (€31.80* / 1 m²)

Content: 0.5 m² (€39.80* / 1 m²)

Content: 0.5 m² (€37.80* / 1 m²)

Content: 0.5 m² (€65.80* / 1 m²)

Content: 0.5 m² (€31.80* / 1 m²)

Noise protection in production halls

By building a noise-control enclosure around machinery areas and equipping the ceilings with high-quality and efficient sound-absorbing products from our range, you can significantly reduce the reverberation time and minimize the reflection of sound waves.

Noise control for machines

In outdoor areas, machinery, technical systems or pumps can be “silenced” with

soni RESIST, for instance. For loud compressors we recommend our soni SB 700 compressor jacket..

Technical noise control from soniflex

We offer you numerous options for achieving sustainable noise reduction through targeted measures and customizable solutions. The soundproofing products from our range not only deliver on their promise in terms of noise reduction, but are also easy to install.

Just give us a call or send us an e-mail. We will be happy to tell you more.