Enhance your production hall | workshop | utility room with our sound absorbers and benefit from:

- a significantly shorter sound reverberation time

- effective insulation of noise-emitting machines and appliances

- a reduced noise level

- a working environment that promotes concentration and hence safety

- more satisfaction and thus higher motivation of your employees

- a healthier and less stressful work environment

Content: 0.5 m² (€21.80* / 1 m²)

Content: 0.5 m² (€31.80* / 1 m²)

Content: 0.5 m² (€39.80* / 1 m²)

Content: 0.5 m² (€37.80* / 1 m²)

Content: 0.5 m² (€65.80* / 1 m²)

Content: 0.5 m² (€31.80* / 1 m²)

Content: 0.5 m² (€27.80* / 1 m²)

Content: 0.5 m² (€29.80* / 1 m²)

Description

Noise control in productions halls | workshops | utility room

Noise is increasingly identified as one of the strongest stress factors at the workplace. Especially in large production halls with numerous loud machines, the noise level can be unbearably high. This not only creates a counter-productive working environment, but also can have a range of negative effects on health. Permanent noise pollution makes concentrated work more difficult and also increases the risk of accidents. Workplace guidelines and the applicable noise protection regulations therefore require that the noise level at workplaces be reduced as much as possible.

Our special acoustic products for production halls and workshops promote a pleasant, motivating and safe working atmosphere. There are multiple applications and uses. For instance, areas where noisy machines are located can be “fenced off” acoustically. Or noise control products can be installed on ceilings and walls to reduce the level of sound reflection. This shortens the reverberation time and thus reduces the overall noise volume to a tolerable level.

Testimonials

Noise reduction in a work space

Sound deadening of a test bench

Noise insulation of a machine housing

Noise reduction in a garage used as work space

Noise reduction in a basement work space

Reducing noise levels in production halls, workshops and utility rooms - effective sound insulation with soniflex

Noise in production halls, workshops and utility rooms is a common problem. Loud machines, tool noise and reverberation from hard surfaces lead to a high level of noise pollution, which has a negative impact on the quality of work, concentration and well-being of employees. Utility rooms with compressors, ventilation systems or heat pumps in particular generate disturbing noise that is transmitted into neighbouring rooms.

With sound insulation solutions from soniflex, reverberation and noise in production facilities, plant rooms and workshops can be effectively reduced, creating a quieter and more pleasant working environment.

Why is sound insulation important in production halls, workshops & utility rooms?

✔ Less noise, better concentration - employees work more productively in a quiet environment✔ Health & safety at work – constant noise can cause stress, hearing damage and fatigue

✔ Pleasant working environment – reduced noise pollution increases well-being in the workplace

✔ Optimisation of technical rooms – reducing noise through ventilation systems, heat pumps & compressors

✔ Compliance with noise protection guidelines – noise protection measures help to comply with legal requirements

Effective sound insulation solutions for production halls, workshops & utility rooms

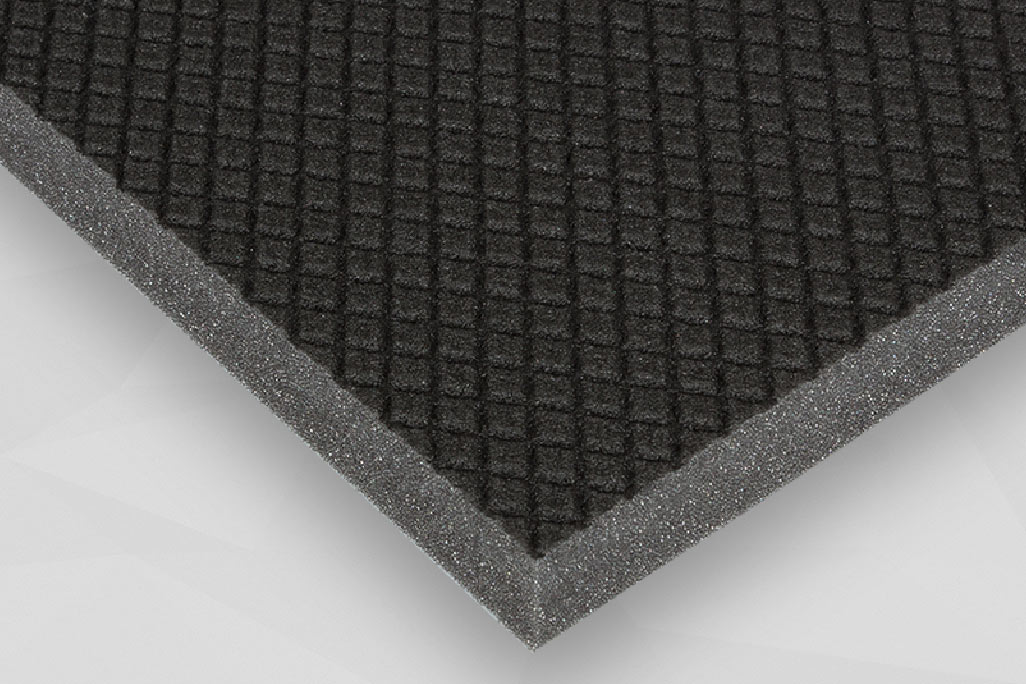

✔ Sound absorbers for ceilings & walls – our soni COMFORT & soni COMFORT SD reduce reverberation and ensure better acoustics.✔ Ceiling sails & baffles – soni TRAPEZ as a suspended baffle minimises disruptive sound in large halls.

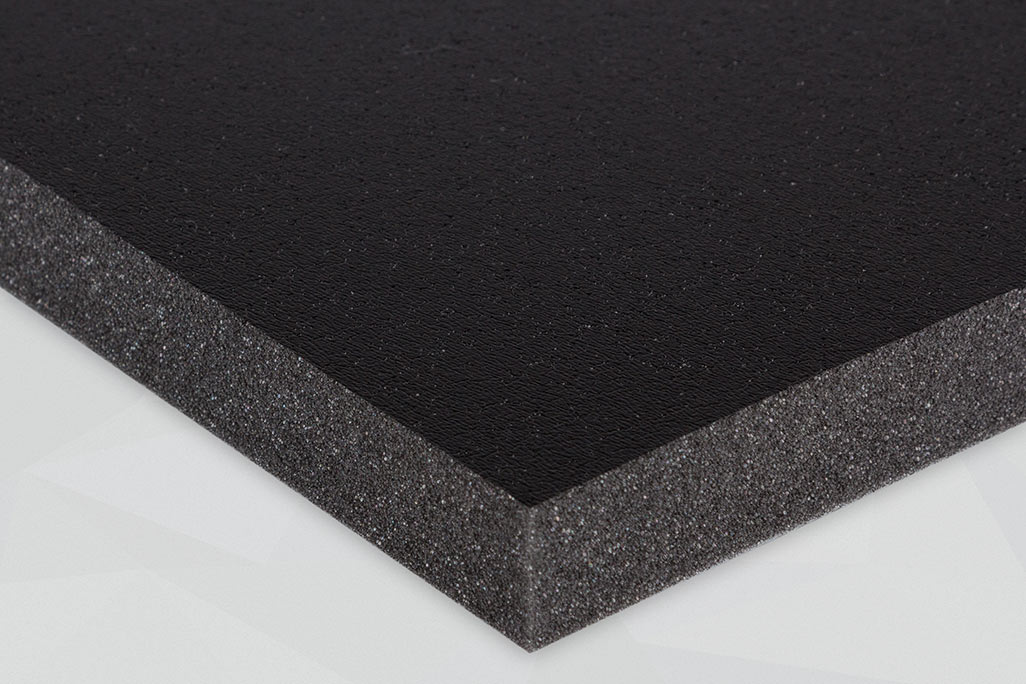

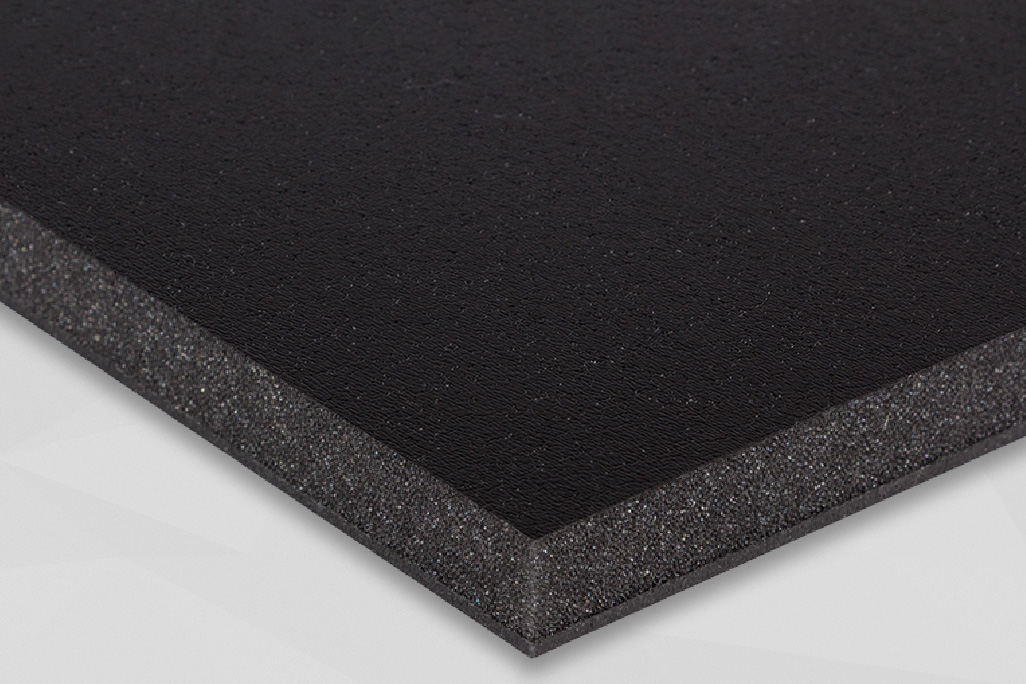

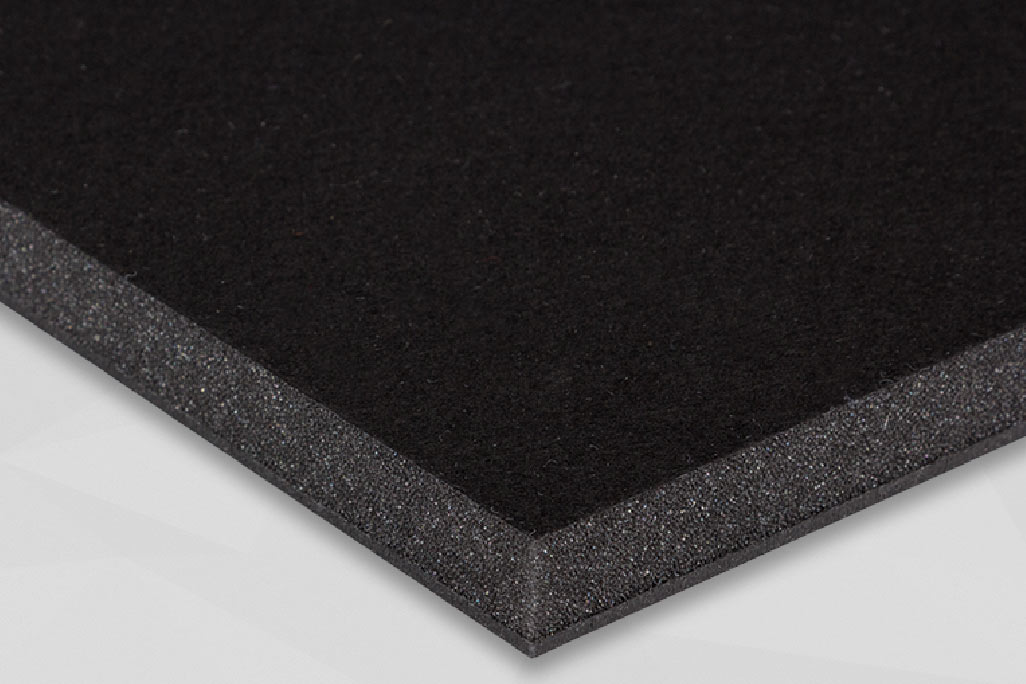

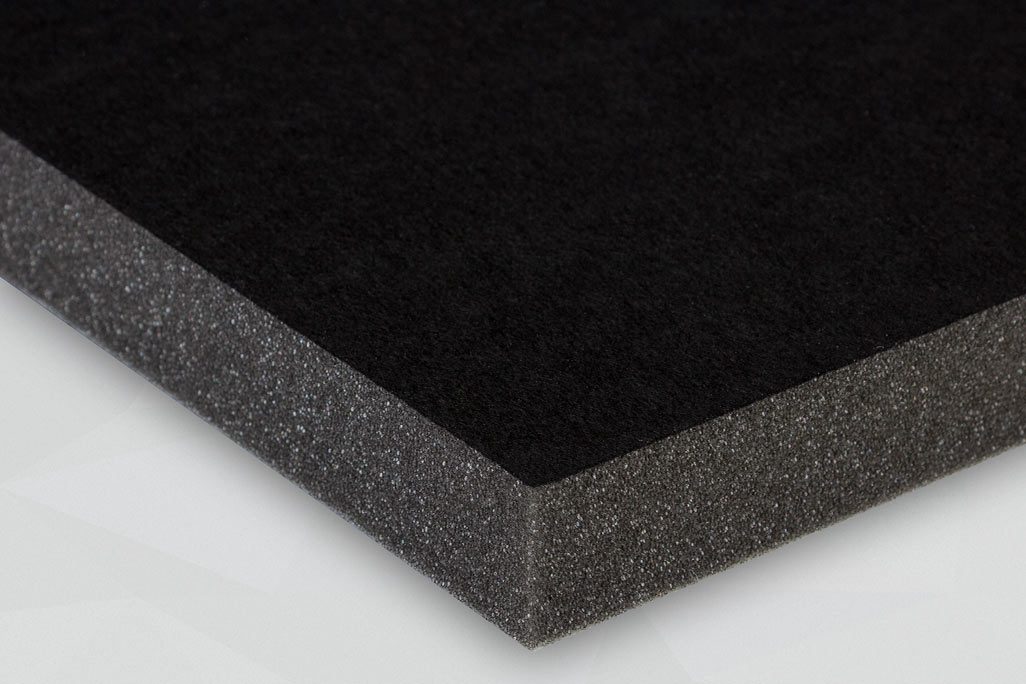

✔ Sound insulation for machines & systems – our PUR foam products soni 471, soni 491, soni WAVE, soni RESIST and soni COMPOSITE effectively insulate and dampen machine noise.

✔ Sound insulation for plant rooms – fan and compressor noise can be insulated with soni RESIST & soni COMPOSITE.

✔ Partition walls & partitions – Flexible solutions for separating particularly loud work areas.

✔ Machine insulation– structure-borne noise insulation for machine housings and workshop equipment.

Our sound insulation products for machinery & utility rooms

✔ soni 471 & soni 491 – high-quality PUR foams for absorbing airborne sound in machine rooms.✔ soni WAVE – foam/nap foam, ideal for industrial applications with a wide frequency range.

✔ soni RESIST – water-repellent sound insulation, particularly suitable for plant rooms, ventilation systems and machine rooms.

✔ soni COMPOSITE – combination of PUR foam and heavy foil for maximum insulation & damping of machines and technical systems.

✔ soni TRAPEZ – ceiling baffles for hall acoustics: As a suspended acoustic element, it specifically reduces reverberation in large production halls & technical rooms.

Simply retrofit sound insulation - for a better working atmosphere

Our soniflex acoustic solutions can be easily and flexibly retrofitted - ideal for existing workshops, production halls and technical rooms. Particularly in large halls with high ceilings and reverberant surfaces, our ceiling sails, machine insulation and partition walls provide a noticeable improvement in room acoustics.The combination of wall absorbers, machine insulation and ceiling baffles can reduce the noise level in a targeted manner and significantly enhance the workplace.

Result

Excessive noise levels in production halls, workshops and technical rooms not only put a strain on employees, but can also impair efficiency and safety in the workplace. With the high-quality sound insulation solutions from soniflex, in particular soni COMFORT, soni COMFORT SD, soni TRAPEZ & our PUR foam products, noise sources can be specifically dampened and working conditions significantly improved.📩 Find out more now & find the right sound insulation solution for your production hall, workshop or technical room!