Heavy foils / anti-drumming layers

Content: 0.5 m² (€39.80* / 1 m²)

Content: 0.5 m² (€65.80* / 1 m²)

Content: 0.5 m² (€27.80* / 1 m²)

Content: 0.5 m² (€29.80* / 1 m²)

Content: 0.5 m² (€43.80* / 1 m²)

Content: 0.5 m² (€65.80* / 1 m²)

Applications for heavy layers

Heavy / sound-deadening layers deliver the double effect of air-borne noise insulation and solid-borne noise attenuation. Especially in areas where metal sheets or other materials tend to vibrate, the heavy layer does an excellent job. When glued onto the material, the heavy layer increases the mass or weight per area unit to an extent that usually leads to a rise in the so-called resonance frequency of the material. As a result, the unpleasant and often botheringly loud droning noise disappears. For this reason, heavy layers are mainly used as anti-drumming measure, which is why they are also called anti-drumming layers.

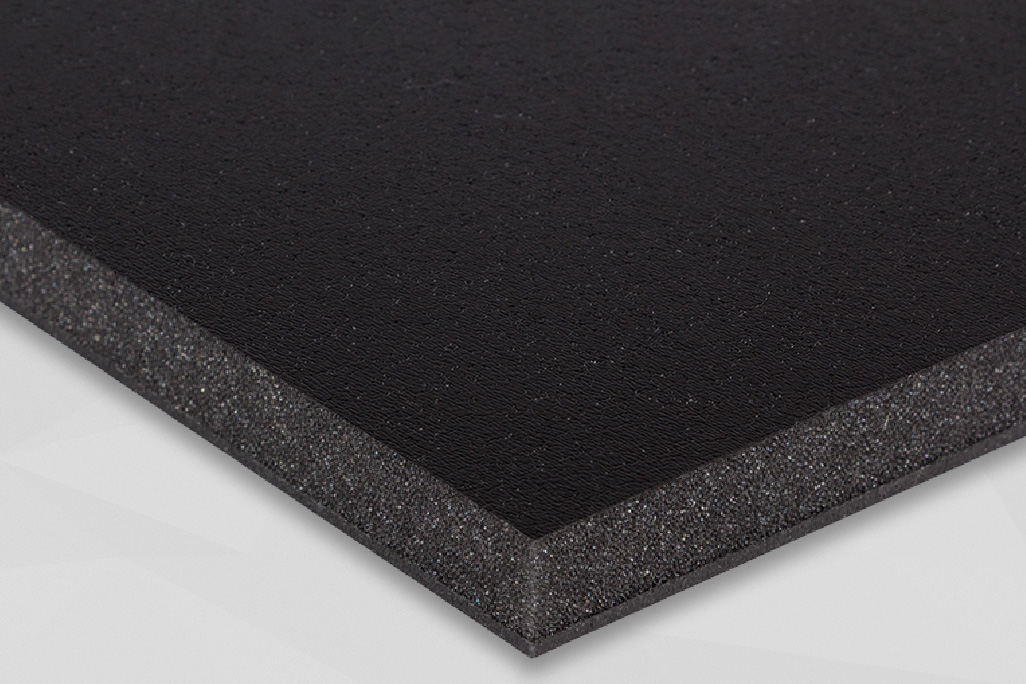

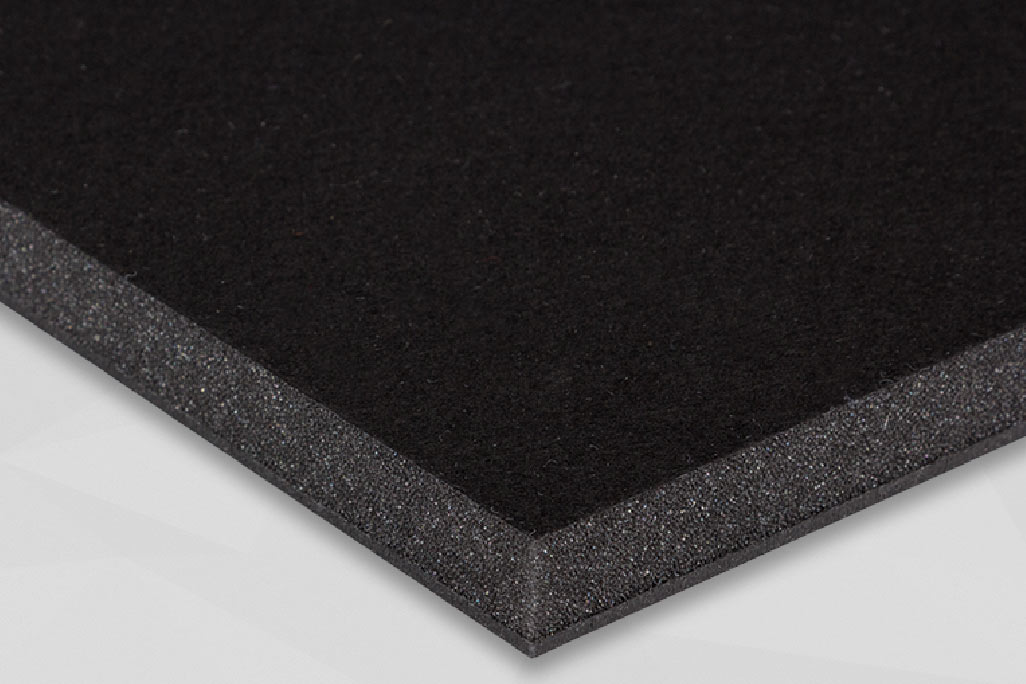

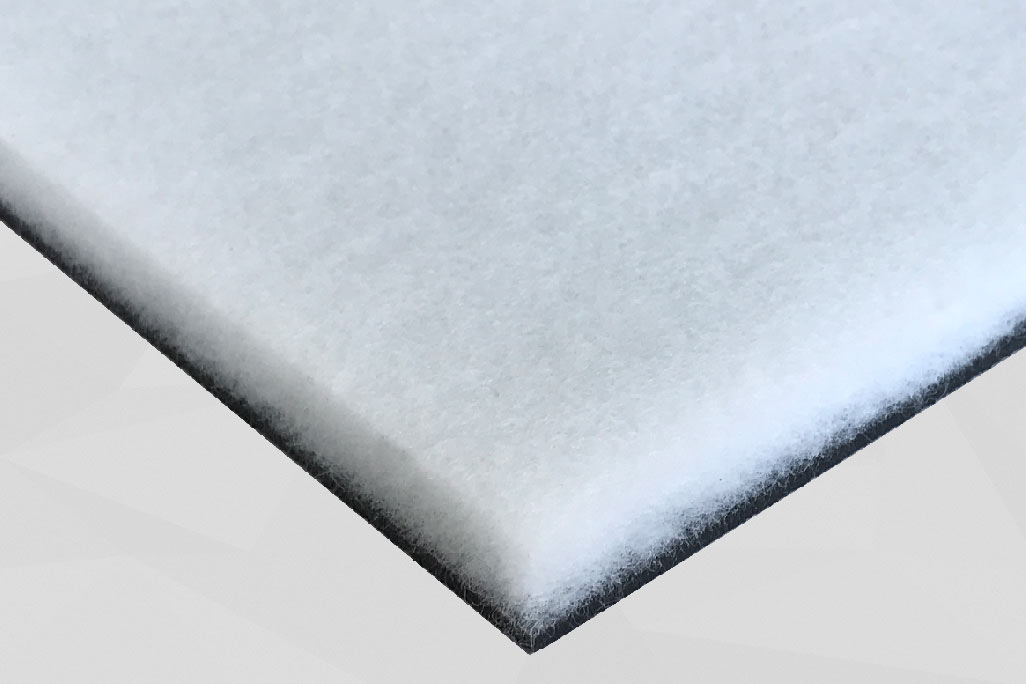

soni COMPOSITE combines the synthetic heavy layer soni EVA 3-01 with a robust PUR ether acoustic foam. The surface is covered with a non-woven that is available in 3 different colors. This ideal combination ensures a twofold noise-control effect: sound absorption plus sound insulation – for especially high overall effectiveness.

Heavy layer products for various applications

The heavy layer products from soniflex can be used for sound insulation, sound-deadening and general noise-control purposes. This wide variety of application areas makes our heavy layer particularly versatile.

Anti-drumming heavy layer for metal sheets and metal parts

Our anti-drumming layers are perfect for noise-insulating and damping metal parts and metal sheets. The use of self-adhesive layers prevents sheet metal from vibrating and droning, thereby minimizing the spread of noise events. The heavy layers are also suitable for use in vehicles or for lining sound insulation hoods and enclosures.

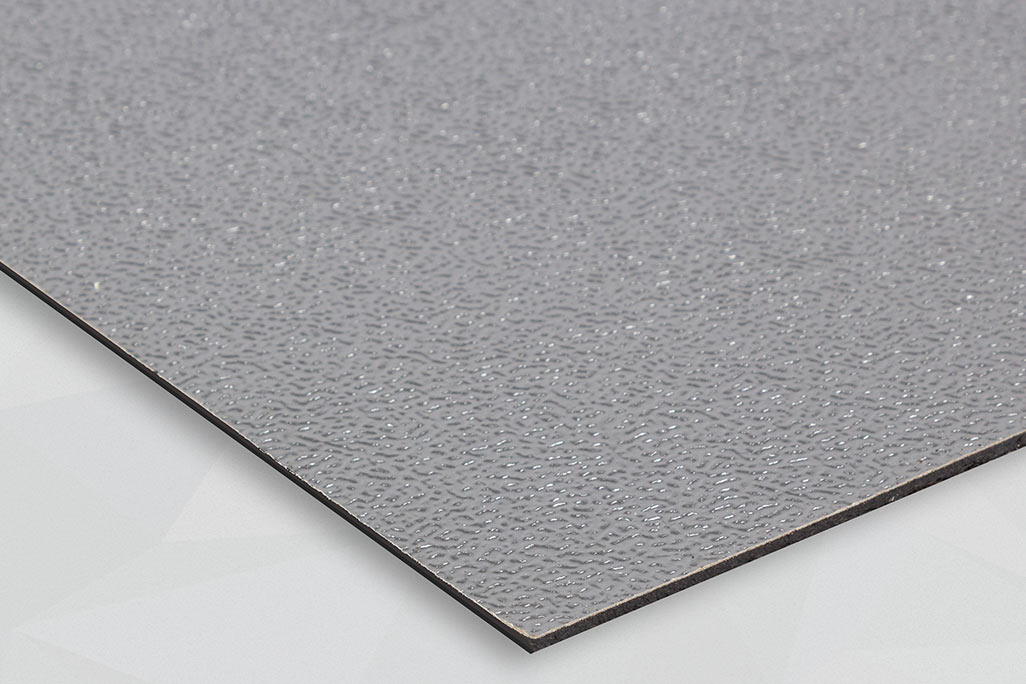

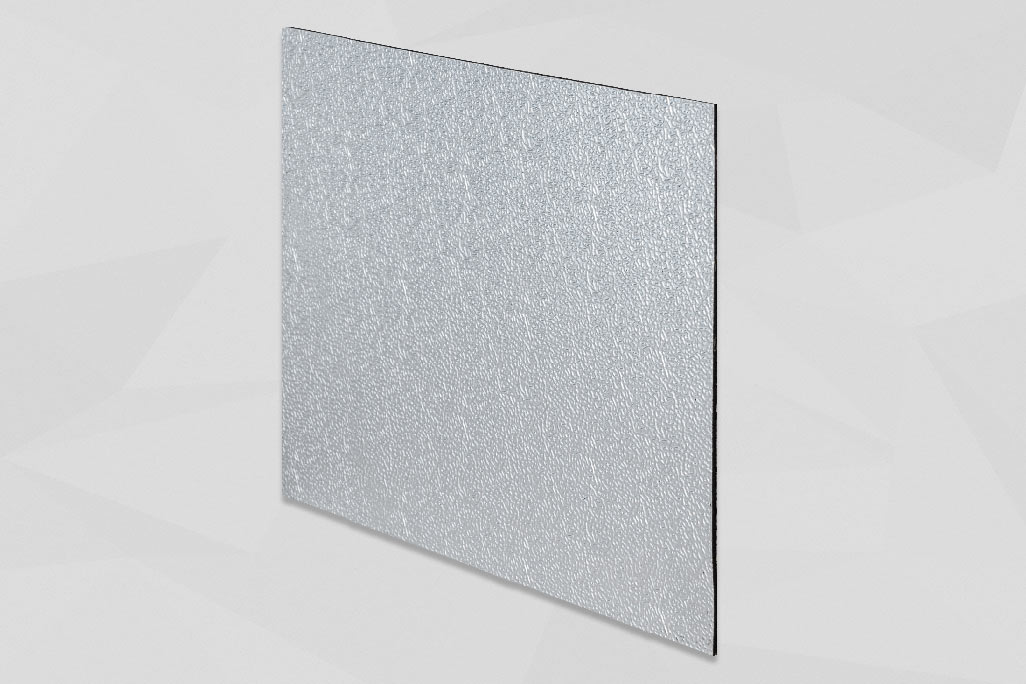

Bitumen-based heavy layer

soni HEAVY and soni HEAVY ALU are elastomer-modified bitumen-based heavy layers. In addition, they are provided with a self-adhesive finish on the reverse side, which makes them even easier to use. The bitumen-based heavy layer is used for damping and insulating metal parts and metal sheets or entire sheet metal structures.

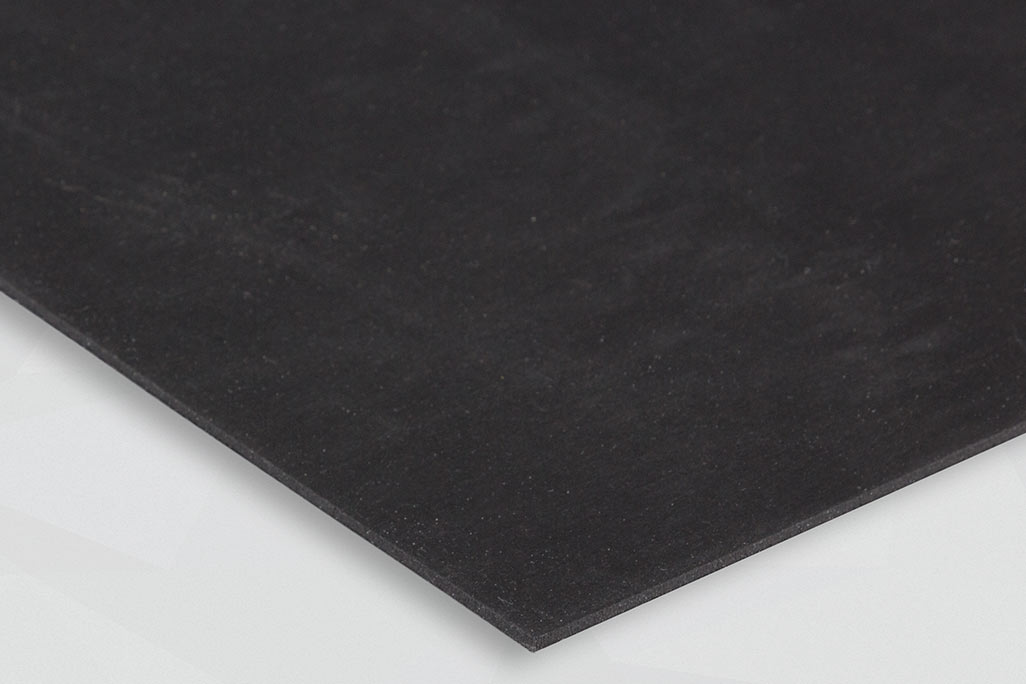

Synthetic heavy layer

If you are looking for a synthetic heavy layer, take a look at soni EVA from soniflex, a soft-elastic anti-drumming / heavy layer. It consists of a mixture of synthetic materials based on EPDM / EVA polymers blended with special flame-retardant minerals. Excellent insulating properties and a high level of fire safety make this product a convincing solution for many areas. Especially interesting: This heavy layer is very easy to install.

Buy heavy layer panels from soniflex

If you are planning to equip metal sheets or sheet metal structures, roller shutter boxes, vehicle spaces or other surfaces with a high-quality heavy layer, soniflex is the place to look. We offer you durable high-quality heavy layer products for the attenuation of structure-borne sound and the insulation of air-borne noise, resp. as anti-drumming layer applied to various materials and structures. The self-adhesive panels are particularly easy to apply and highly effective.